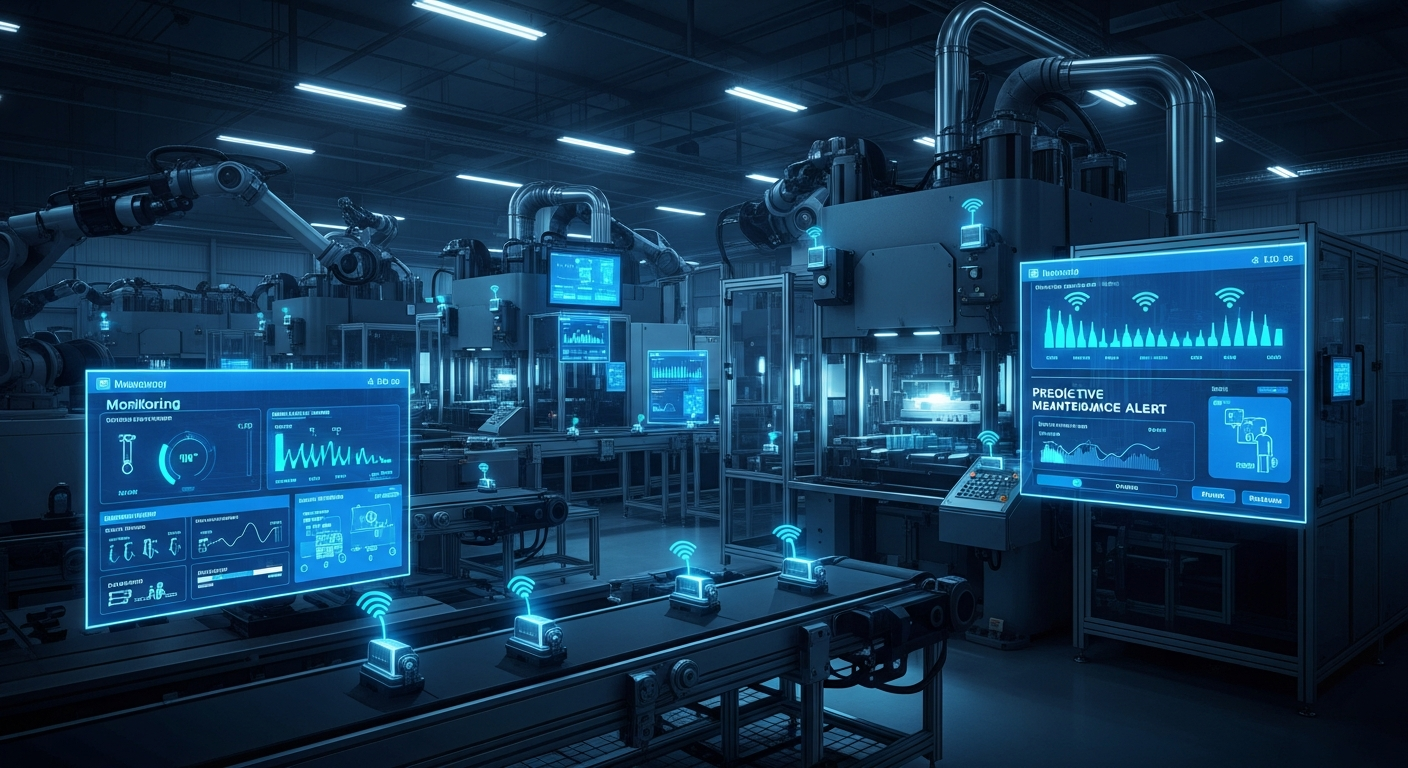

Eliminate Unplanned Downtime with Predictive Intelligence

Deploy wireless industrial sensors in minutes, not months. Monitor vibration, temperature, pressure, and more across your entire facility. Our AI-powered platform predicts failures weeks in advance, saving manufacturers an average of $200K+ annually.

Competitive Advantages

Purpose-built for industrial environments where reliability is non-negotiable

ATEX/IECEx Certified Options

Intrinsically safe sensors for Zone 0, 1, and 2 classified areas. Deploy in refineries, chemical plants, grain elevators, and pharmaceutical facilities where sparks aren't an option. Full certification documentation for your safety audits.

5-10 Year Battery Life

Your maintenance team has enough to do without chasing battery replacements across the plant. Our sensors run 5-10 years on industrial lithium cells, even reporting every 15 minutes in 24/7 operations. Deploy once, collect data for a decade.

No Wiring, No Downtime

Wiring a sensor to a legacy machine might take weeks of engineering review, conduit runs, and electrician scheduling. Our wireless sensors stick on with industrial adhesive or magnetic mounts. One maintenance tech can instrument 20 machines in a single shift—during production.

Retrofit Any Equipment

That 1985 stamping press with no PLC outputs? The German CNC with proprietary controls? Our sensors don't care. They measure vibration, temperature, and current externally—no integration required, no OEM approval needed. If it vibrates, heats up, or draws power, we can monitor it.

Industrial Monitoring Solutions

Comprehensive sensor coverage for any manufacturing or processing environment

I've seen maintenance teams spend decades running on fixed schedules—changing bearings every 6 months whether they need it or not. Meanwhile, the pump in the corner fails catastrophically because nobody checked it. Our vibration sensors learn what 'healthy' sounds like for each piece of equipment. When bearing wear starts showing up in the frequency spectrum 3-4 weeks before failure, you'll know. That's the difference between a planned $2,000 repair and a $180,000 unplanned shutdown.

Sensor Suite

Proven Results

- 60% reduction in unplanned downtime

- Predict failures 2-4 weeks in advance

- Extend equipment life by 25%

- Eliminate catastrophic failures

When a reactor temperature drifts 5°C outside spec, you've got minutes to react before product loss—or worse. Our industrial probes read from -200°C cryogenics to +850°C furnaces with ±0.2°C accuracy. Pressure transducers handle 0-1000 bar. The moment any parameter crosses your defined threshold, alerts fire to operators, supervisors, and your SCADA system simultaneously. No more relying on someone to walk by and check a gauge.

Sensor Suite

Proven Results

- Real-time process visibility

- Automated compliance logging

- Prevent thermal runaway incidents

- Optimize energy consumption

How much time does your team waste hunting for equipment? That $50,000 calibration tool that 'should be in Area 7.' The portable welder that three shifts borrowed and nobody returned. Our tracking tags attach in seconds and report location every 15 minutes across your entire facility. One client discovered they owned 40% more torque wrenches than they thought—just scattered across their 500,000 sq ft plant.

Sensor Suite

Proven Results

- 75% reduction in search time

- Reduce tool loss by 90%

- Automated inventory counts

- Workflow optimization insights

Environmental compliance isn't just about avoiding fines—it's about protecting your people. Our multi-gas detectors measure CO, CO2, H2S, and LEL continuously at breathing zone height. When concentrations spike, every worker's phone gets an alert within seconds, not the 30+ minutes it takes for periodic spot checks. One chemical plant client detected an ammonia leak at 15ppm, evacuated in 4 minutes, and prevented what could have been a serious exposure incident.

Sensor Suite

Proven Results

- Real-time safety alerts to all workers

- Automated OSHA compliance reporting

- Early leak detection (seconds, not hours)

- Historical data for incident investigation

Tier 1 Automotive Supplier, Guangdong Province

The Challenge

This stamping plant was averaging 12+ unplanned breakdowns per year on their 15 critical presses. Each incident cost roughly $180,000 in lost production, emergency parts, and overtime to catch up. The maintenance team was skilled, but they couldn't predict which bearing would fail next week.

The Solution

We deployed 85 vibration sensors across all 15 presses, plus temperature monitoring on main motors and hydraulic systems. The sensors feed into our analytics platform which learned each machine's baseline vibration signature over 30 days. Now, when bearing wear starts showing characteristic frequency patterns 3-4 weeks before failure, the CMMS automatically generates a work order.

"The first time we caught a main bearing going bad with 3 weeks notice, the skeptics on my team became believers. We ordered the part, scheduled the repair for a planned maintenance window, and avoided what would have been a 36-hour emergency shutdown. That single save paid for half the project."

What Plant Managers Are Saying

"We have 180 pumps across our water treatment facility—impossible to check them all manually with any frequency. Within 60 days of deploying vibration sensors, we caught a cavitation issue on a critical lift pump that would have burned out the motor. Replacement cost avoided: $85,000."

"The hardest part of predictive maintenance is getting buy-in from operators who've 'always done it this way.' When we prevented the third breakdown in a row using sensor data, even the old-timers started checking the dashboard. Culture change through results."

"Our injection moulding machines run 24/7 making precision components for medical devices. Unplanned downtime isn't just expensive—it disrupts supply chains for life-saving equipment. These sensors give us the early warning we need to schedule maintenance without impacting production."